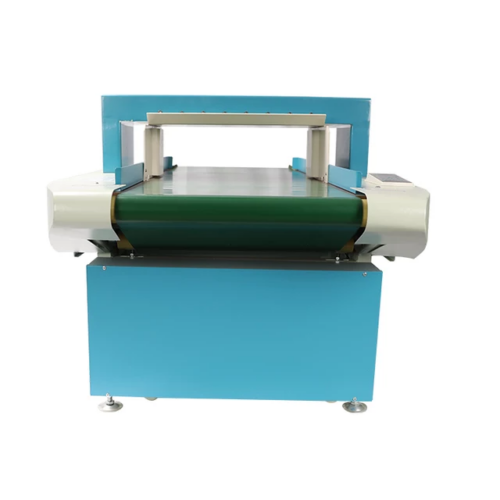

liquid and beverage processing pipeline metal detector (

General introduce of pipeline feed metal detectors

It comes from the principle of electromagnetic induction. It is a high precision detection equipment for magnetic and nonmagnetic metal and a metal separator equipment. Can detect materials

including iron (magnetic) and non-iron(nonmagnetic: copper, aluminum, tin, Stainless Steel, etc.) If ferromagnetic metals into detection area will affect regional distribution of magnetic line,

also change the magnetic field distribution. Non ferromagnetic metals into detection area will produce eddy current effect, also will change the magnetic field distribution.

Normally, Metal Detector combines with two parts, induction coil and automatic removing device, in those, core part is detector.

3)Diameter 25 Technical Parameter (high precise)

Series of detection sensitivity: Fe≥φ 0.6mm Sus≥φ 1.0 mm Ca≥φ 1.0 mm

Main metal detector dimension( except hopper and support)

Equipment shell material: A3 steel plate painting coated or #304 stainless steel plate

Total power

Power cable:3m international triangle plug

Working pressure

Environment temperature

Detection material temperature

Contact part with raw material: Nylon, carbon steel, stainless steel, Aluminum

Compressed air 8mm international standard pipes connection

Gas: 04.L/separator action

Total Weight

Detection precise: volume metal particle (normal metal),can adjust according to different situation

Action Time: 0.5S to 5 S, longer time the more waste discharge

| Pipe Diameter | 25MM | 35MM | 50MM | 80MM |

| Detect Capacity | 200KG | 500KG | 800KG | 2000KG |

| Machine weight | 25KG | 35KG | 35KG | 35KG |

| Sensitivity | FE≥φ0.4mm SUS≥φ0.8mm CA≥φ0.8mm |

FE≥φ0.5mm SUS≥φ1.0mm CA≥φ1.0mm |

FE≥φ0.6mm SUS≥φ1.0mm CA≥φ1.0mm |

FE≥φ0.8mm SUS≥φ1.2mm CA≥φ1.2m |

| Machine dimension mm | 318X230X326 | 318X230X320 | 318X230X320 | 378X270X350 |