Advancing Security: Needle Detection for Large Carton Boxes**

In the world of logistics and manufacturing, ensuring the safety and integrity of products is paramount. The incorporation of a Needle Detector for Big Carton Boxes emerges as a crucial solution to fortify quality control processes and protect consumers from potential hazards. This article explores the significance, features, and applications of Needle Detectors in the context of large carton box inspections.

Understanding Needle Detectors:**

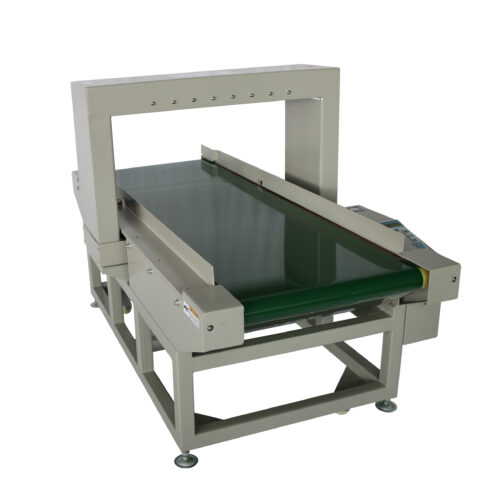

Needle Detectors, also known as metal detectors, are specialized devices designed to identify the presence of metallic contaminants within various materials. In the context of large carton boxes, these detectors play a vital role in preventing the distribution of products that may contain metal fragments, such as needles or other sharp objects.

**Key Features of needle detector for Large Carton Boxes:**

1. **Wide Detection Area:** Needle Detectors configured for large carton boxes are equipped with a wide detection area to efficiently scan the entirety of the box, ensuring comprehensive coverage.

2. **High Sensitivity:** The detectors boast high sensitivity to detect even small metallic contaminants, providing an extra layer of assurance in product safety.

3. **Adjustable Sensitivity Levels:** The ability to adjust sensitivity levels allows for customization based on the specific requirements of the product being inspected, optimizing the detection process.

4. **Conveyor System Integration:** Needle Detectors designed for large carton boxes often feature conveyor systems, facilitating the seamless movement of boxes through the detection process.

5. **User-Friendly Interface:** Intuitive controls and a user-friendly interface make operation straightforward, ensuring that operators can efficiently manage the inspection process.

**Applications of Needle Detectors for Large Carton Boxes:**

1. **Manufacturing Plants:** Implementing Needle Detectors in manufacturing plants ensures that carton boxes containing finished products are free from metallic contaminants before distribution.

2. **Logistics and Warehousing:** Needle detection becomes crucial in logistics and warehousing, where large carton boxes are handled and stored before reaching their final destinations.

3. **Food Industry:** In industries dealing with packaged food items, Needle Detectors contribute to food safety by preventing the distribution of products with potential metal contaminants.

4. **Textile Industry:** For products packaged in large carton boxes within the textile industry, Needle Detectors ensure that garments and textiles are free from stray needles or metal elements.

**Benefits of Needle Detection in Large Carton Boxes:**

1. **Consumer Safety:** Implementing Needle Detectors safeguards consumers from the potential harm of ingesting or encountering metal contaminants in products.

2. **Quality Assurance:** By incorporating Needle Detectors in the quality control process, manufacturers can uphold product quality standards and compliance with safety regulations.

3. **Operational Efficiency:** The integration of conveyor systems and adjustable sensitivity levels enhances the efficiency of the inspection process, allowing for high throughput without compromising accuracy.

4. **Brand Reputation:** Upholding product safety standards through the use of Needle Detectors contributes to building and maintaining a positive brand reputation.

**Conclusion: Elevating Product Safety with Needle Detection**

In the dynamic landscape of manufacturing and logistics, the integration of Needle Detectors for Big Carton Boxes stands as a pivotal measure to ensure product safety and quality. As industries continue to prioritize consumer well-being and adhere to stringent safety standards, Needle Detectors emerge as essential tools in fortifying the integrity of products before they reach the hands of consumers. Invest in the future of product safety – explore the capabilities of Needle Detectors for large carton boxes today.