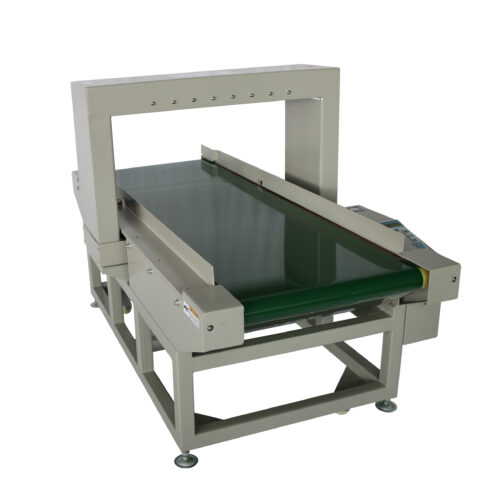

Double headed magnet conveyor needle detector machine

The Double headed magnet conveyor needle detector machine is a type of magnetic conveyor machine, which is used to detect the presence of metal objects. This machine is widely used in industries such as food, chemicals, metallurgy and other technical fields.

The main features of our double headed magnet conveyor needle detector machine are as follows:

1. The detector can be installed on all types of materials, and it can also be installed in any specific location;

2. It has a high-precision detection system with two heads and four poles;

3. The detection speed is high and the system is stable;

4. It has a large detection area and smooth operation;

5. It can be customized according to customer requirements;

New coil units are capable of detecting foreign objects and homogenizing the aperture of the sensor.

It reduces the “Material effect” and improves product passage.

Inspection system needle detector

The inspection accuracy was improved by the addition of a front and rear sensor. Each angle can be changed to improve it.

Double headed magnet conveyor needle detector machine (magnet conveyor) is composed of magnet, needle detection mechanism and the motor. The magnetic field generated by the motor will move the magnet in the direction of its rotation. This movement of the head causes it to touch a certain distance from the needle on its way.

The controller will calculate an average speed for each revolution of the motor and compare it with a threshold value. If this difference is greater than a preset limit, a signal will be sent to stop the machine, otherwise no signal will be sent.

- Reduced time for pre-checking.

The system automatically checks the sensor and does not need to check each coil individually.- Environment Check Mode

This mode is patent-pending and can be used to check the surrounding environment.

- Scalability to peripheral devices

It is possible to connect RFID reader, Barcode reader and so forth.

An optional automatic sorter, HS-601, can be attached to the needle detector.- An operator can choose 2 types of sensitivility (100step) or sizing method (6step)

- Equipped w/ a production guider.

New mechanisms produce low mechanical noise and sound.

- You can download the history record, etc.

- 7-inch color LCD monitor equipped with touch panel.

Reduced time for pre-checking.

The system automatically checks the sensor and does not need to check each coil individually.

Environment Check Mode

This mode is patent-pending and can be used to check the surrounding environment.

Scalability to peripheral devices

It is possible to connect RFID reader, Barcode reader and so forth.

An optional automatic sorter, HS-601, can be attached to the needle detector.

An operator can choose 2 types of sensitivility (100step) or sizing method (6step)

Equipped w/ a production guider.

New mechanisms produce low mechanical noise and sound.

You can download the history record, etc.

7-inch color LCD monitor equipped with touch panel.