Inline metal detection in food industry

What are the benefits of metal detectors in the food industry?

Food metal detectorsare primarily used to protect the consumer. Metal contamination of food products can still occur even with the best care. Consumers may be seriously injured if metal particles are introduced to the product in the manufacturing process. Producers may face serious consequences, including costly recalls and compensation claims. The negative brand image and loss of trust in consumers due to impure foods can cause even greater and more lasting damage.

Food metal detectors provide protection against non-ferrous and ferrous metals (aluminium or stainless steel) effectively. They can be used in any stage of production and are versatile enough to be used for many purposes, such as. They can be used to inspect bread, bakery products, meat, sausage products, fruits, vegetables, dairy products and spices, as well as sugar.

Metal detectors are not only used for consumer protection but also to protect machinery. Even the smallest metal particles can cause machinery to fail. The consequences are often costly repairs and downtimes that lead to production failures, which is often followed by revenue drops.

Are metal detectors used in food production?

The metal detector is used to protect machinery. It is placed directly in front of the machine. Multiple inspection points can be useful if, as is often the case in the food industry for consumer protection, multiple inspection points are necessary. Inspection of raw material offers the advantage that metal particles can be separated before being broken down into smaller pieces, which may make it harder to spot. To detect machinery failures, such as broken blades, it is a good idea to inspect critical control points (HACCPs), during production.

Food products at their final stage are therefore inspected with an X-ray or metal detector to exclude any contamination.

It is recommended that you inspect the raw materials and perform a final inspection on the product to ensure maximum product protection.

How does a metal detector work?

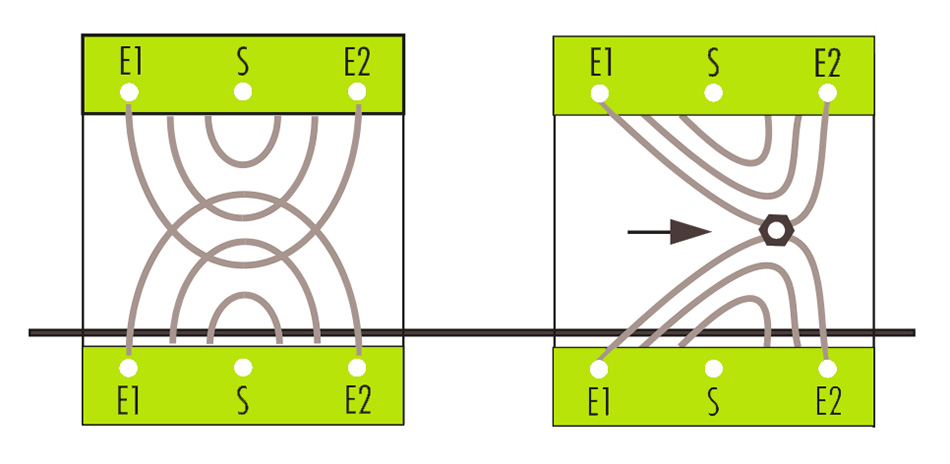

There are many types of metal detectors, each with its own detection method. Metal detectors are used in the food industry with the transmitter-receiver technique (see graphic).

These metal detectors come with two receiver coils and a transmitter coil. The transmitter coil creates an electromagnetic field. The receiver coils detect a signal when a metal particle passes through the detector. The metal detector’s electronic unit analyzes the signal and determines if it is contaminated. Metal detectors used in the food industry have automatic reject units, which are able to remove contaminated products from the production line.